What is casting?Updated 16 days ago

Jewellers use the process of casting to create the metal portions of jewellery pieces, for everything from rings to bracelets to pendants of gold and platinum.

A CAD (Computer Aided Design) file for your design is created, which is then used to 3D print a resin or wax model of your design.

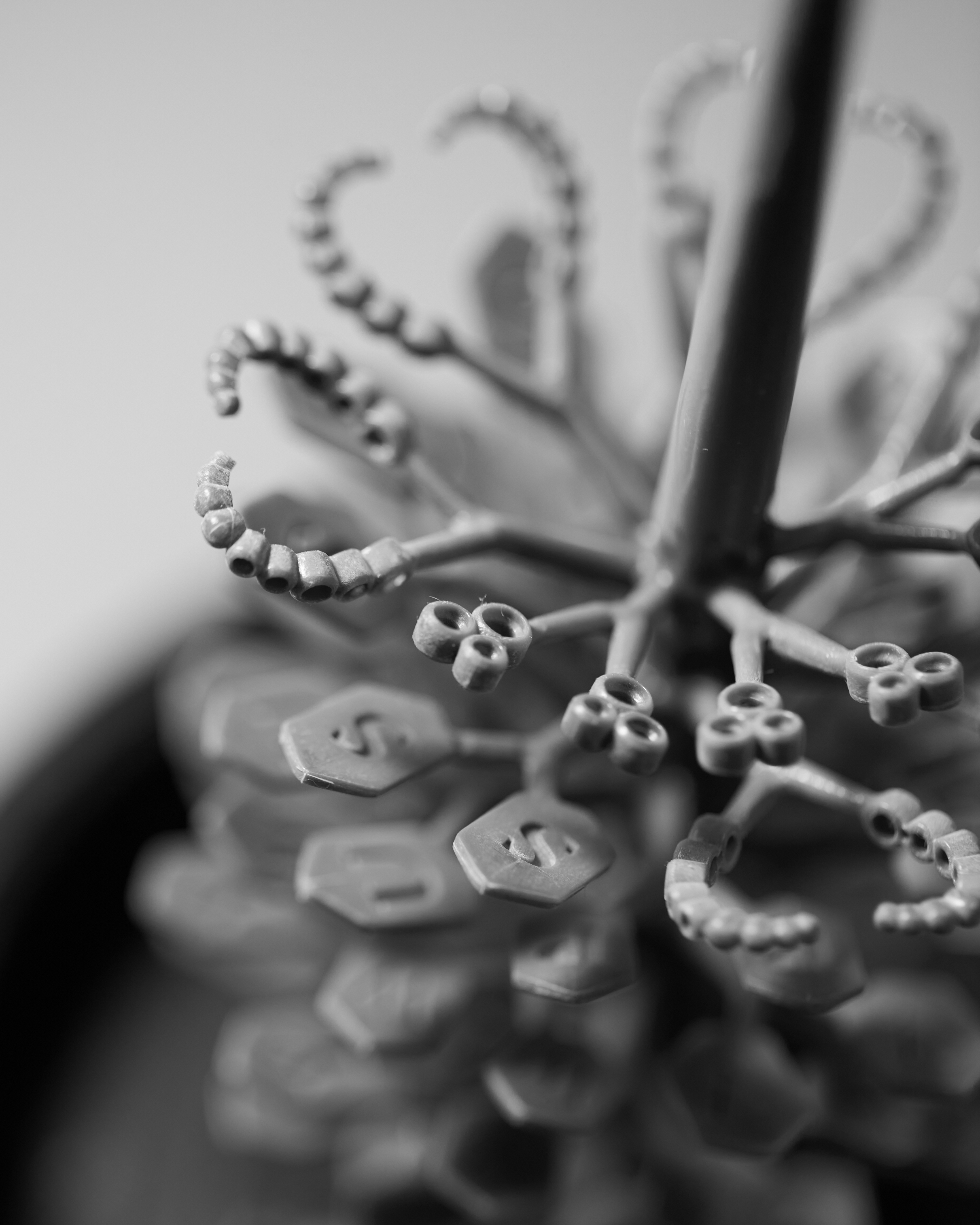

The resin or wax model is attached to a sprue, which is then attached to the main stem to form a tree. The stem and sprue will be the channel for which the molten metal will enter the mould.

From there the ‘tree’ is placed in a steel flask which is then filled with a slurry of ceramic powder which solidifies.

The flask is then heated in an electric furnace which melts the resin or wax tree, leaving behind a cavity of all the models. Molten metal is poured into the flasks, allowed to cool, and demolished to reveal the piece in cast form.

Once the raw casting is removed from the casting tree, it is time for the clean-up! This involves sawing and buffing off the excess metal and casting sprues.